Building energy-efficient homes is more affordable than you may think

ENBIX encourages builders, renovators and consumers to choose better energy performance, and we have resources available to help.

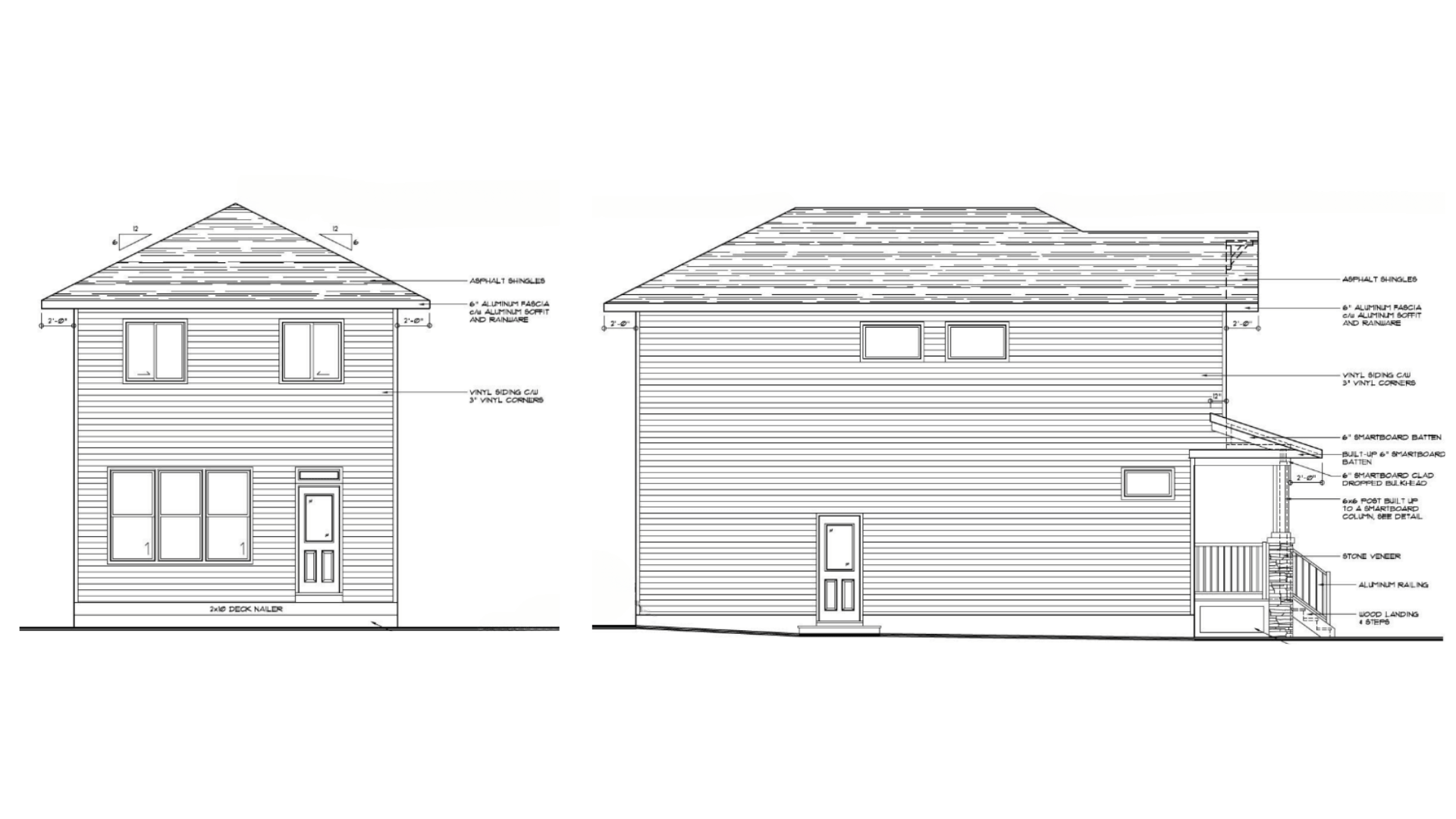

We commissioned the Southern Alberta Institute of Technology (SAIT) to build six wall assembly solutions for a virtual and physical wall library. The goal is to equip the building industry with tools and insights that help transform new home construction and retrofits into energy-efficient powerhouses. Explore the full collection in our virtual ENBIX wall library.

Whether you’re a builder, energy advisor or homeowner, the ENBIX wall library is intended to help improve the efficiency, resiliency and sustainability of Alberta homes. Each wall includes videos, detailed drawings, constructability and affordability analysis, thermal performance data, and construction photos. The physical walls constructed for the project are being housed at Red Deer Polytechnic, while 3D models and some of the details are viewable online at the ENBIX Wall library link above.

This blog outlines some of the project’s key learnings and provides individual links to each digital wall assembly.

The high-performance puzzle

Most homeowners and builders want energy-efficient homes. They are better for the environment, more comfortable to live in, and cheaper to operate. But the path to success for achieving high-performance construction goals is often unclear, especially around cost and complexity. Which wall design is best? How much more will it cost? Does it require specialized trades?

The core problem has been a lack of data on how different high-performance wall designs actually compare in the real world in Alberta’s climate. To help solve this puzzle, SAIT decided to tackle this project on behalf of Alberta Ecotrust Foundation. SAIT researchers physically built, costed and analyzed six different residential wall assemblies to get answers.

Net-zero doesn’t have to be complicated

The government of Canada considers a building “net-zero” when it either emits no greenhouse gas emissions or offsets its emissions. A common misconception in the building industry is that achieving net-zero energy standards requires new technology or special building techniques. The SAIT research challenges that view.

When the team built six wall types, they found the net-zero, double stud wall (R-32.52) to be the second easiest to build, and the baseline code wall the easiest. The net-zero double stud wall simply uses two regular 2×4 walls with insulation in between, using skills framers already know. In comparison, the exterior foam net-zero wall was the hardest to build and needed more careful planning.

This is an important finding for builders hesitant to enter the high-performance market. It shows they can achieve net-zero performance targets without budgeting extra for special training or searching for specialized stores to source materials. Their existing crews already have the skills needed.

The most expensive option is a massive jump

Energy efficiency is the goal, but budget is the reality for any project. The SAIT cost analysis revealed a big gap between the two net-zero wall types, pointing to diminishing returns on insulation.

For a full-model home analysis, the double-stud net-zero wall was only 23 percent more expensive than a baseline code wall, while the exterior foam net-zero wall cost 160 percent more. Key reasons for the cost increase were:

- The smart SIGA Water Resistive Barrier (WRB) membrane.

- The 6 inches of exterior XPS foam insulation.

- The very long and expensive structural fasteners are required to hold it all together.

The differences become even more pronounced when analyzing the cost of the wall materials alone. In that scenario, the exterior foam net-zero assembly was a staggering 465 percent more expensive than the baseline (code) wall.

This data provides strategic insight for project planning. The double stud wall represents a “sweet spot” for cost-effective, net-zero construction, while the exterior foam net-zero is a no-compromise, premium option where budget is a secondary concern to achieving the absolute maximum R-value (R-46.62).

A deep retrofit can be cheaper than a basic new build

SAIT found that retrofitting an existing home can sometimes cost less than building brand new.

Using the Larsen Truss retrofit assembly (on a modelled home), the material cost of a deep energy retrofit was about seven percent less than constructing the same home as a new build with a basic code-minimum wall. The Larsen Truss adds a site-built truss system to the outside of the existing walls, creating additional space for dense-pack cellulose insulation.

The main reason is material cost. Retrofits keep the existing structure and only require new exterior materials, while new builds must include the full interior and exterior materials and wall structure. For cities with climate goals and a large stock of older homes, this makes a strong case for prioritizing retrofit programs over new builds.

Insulation isn’t the only costly material

Expensive materials like insulation or windows aren’t the only cost drivers. The SAIT report found that water-resistant barriers, vapour barriers and sealant tapes can each have a major impact on cost.

For example, the exterior mineral wool Tier 3 wall costs 54 percent more than baseline, mainly because of high-quality membranes and tapes. This shows that the air control system (membranes, sealants and tapes) can be just as costly as insulation.

You don’t have to go “all in” to save

The report also showed you don’t need a full net-zero build to see big savings. Upgrading from a standard code, minimum R-17 wall to an R-26 exterior mineral wool Tier 3 wall cuts annual heat loss by about 10 GJ, or 8% of total energy use. Improving air tightness saved another 10 GJ. Together, these two simple upgrades delivered a 16% reduction in annual energy use.

The path to high-performance and better homes isn’t all or nothing. Industry now has a much clearer understanding of these tradeoffs. Whether you’re planning a retrofit, new build or small upgrade, the message is all the same. Building better is within reach. Learn more about the broader benefits of building beyond code in this ENBIX article.

ENBIX wall library assemblies

Larsen Truss Retrofit

A net-zero exterior retrofit designed for mid-century homes. It blends affordability with performance – in this case, easily sourced materials, flexible insulation depth and a 32.6 percent reduction in energy use.

Fire-Resistant Retrofit

Adds durable, fire-resistant mineral wool exterior insulation, minimizing thermal bridging and enhancing safety.

Exterior Mineral Wool - Tier 3

Wraps standard 2×6 framing with two inches of mineral wool, offering moisture and fire resistance while preserving traditional construction methods.

Double Stud Net-Zero

An easy-to-build, two-wall assembly using common materials. Affordable, accessible and effective at reducing thermal bridging.

Exterior Foam Net-Zero

A simple, cost-effective assembly that uses continuous exterior foam insulation to achieve net-zero performance while keeping construction straightforward.

Business-as-Usual Tier 1

A baseline 2×6 wall with batt insulation. Serves as a baseline reference point for comparing higher-performance retrofit and new-build assemblies, and what the Cities of Edmonton and Calgary are most commonly seeing in residential construction in 2024.

Read the full report from SAIT to take a closer look at:

- Wall assembly drawings, sections and details.

- Photos of construction.

- Constructability and affordability analysis.

- Effective thermal resistance calculations.

- Comparison charts with other walls in the ENBIX library.