In today’s building design and construction world, environmentally friendly choices are becoming a regular part of the decision-making process. There is growing demand from architects, designers, builders and clients for access to clear, reliable information about the environmental footprint of their building materials. This is where Environmental Product Declarations, or EPDs, come in.

What is an Environmental Product Declaration (EPD)?

Think of an EPD as a nutritional label, but instead of detailing calories and vitamins, it outlines a product’s environmental impact throughout its entire lifecycle. From the moment raw materials are extracted from the earth to the product’s eventual disposal, an EPD provides a standardized and verified snapshot of its environmental performance. This comprehensive overview is achieved through a process called Life Cycle Assessment, which analyzes the environmental impacts at each stage.

It’s important to note that EPDs are not a rating system that declare one product “better” than another. Instead, they serve as an objective information source empowering purchasers – whether individuals, businesses or governments – to make informed decisions based on their specific environmental priorities.

What are the benefits of an EPD?

- For purchasers: EPDs make it easier to make informed choices by highlighting more sustainable options and encouraging demand for environmentally responsible products.

- For manufacturers: They provide a valuable way to showcase the environmental strengths of their products, helping them stand out in a competitive market.

- For industries: EPDs promote greater transparency, giving all parties a clearer picture of a product’s true environmental footprint throughout its lifecycle.

- For green building projects: EPDs can contribute to earning credits in well-known certification programs like LEED.

- For companies facing environmental regulations: EPDs serve as a useful tool to demonstrate compliance with evolving standards.

What information does an EPD include?

While EPDs are increasingly used as standardized tools to report the global warming potential of construction materials, it is important to understand that not all EPDs are the same.

Governed by a series of International Standards Organization (ISO) standards, EPDs primarily fall under the Type III environmental declaration category, which, unlike Type I or II claims, must be third-party verified and provide quantified life cycle information, making them ideal for comparing products. However, significant variations exist within these Type III declarations. The specificity of an EPD can range from an industry-wide average, which offers a general impact but isn’t useful for direct product comparisons, to more granular product-specific, supply chain-specific and facility-specific EPDs that detail the impacts of a particular product from a single manufacturer or even a specific plant.

Some examples of environmental impact indicators that can be found in an EPD include:

- Global warming potential: Measures the product’s contribution to climate change, often expressed in kg CO₂e.

- Resource depletion: Captures the use of raw materials, including fossil fuels and non-renewable resources.

- Ozone depletion potential: Measures the product’s impact on the ozone layer.

- Energy consumption: Tracks the energy used during production, transportation and use.

- Water use: Measures the amount of water used throughout the product’s lifecycle.

- Emissions: Quantifies emissions to air, water and soil.

- Waste generation: Tracks the amount of waste generated at each stage of the product’s life.

To learn more about EPD requirements and policies, visit the Carbon Leadership Forum’s website.

What are the steps involved in creating an EPD?

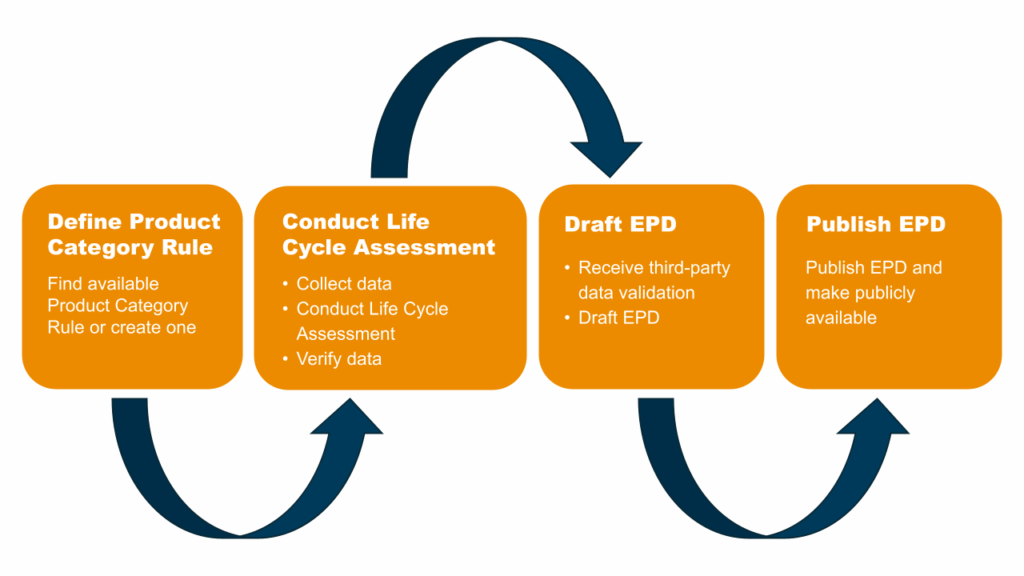

- Define Product Category Rules: An EPD is developed according to specific Product Category Rules and adheres to international standards, like ISO 14025. These rules and standards ensure a level playing field for comparison by dictating how data is collected and analyzed, guaranteeing consistency and reliability across different products within the same category.

- Conduct Life Cycle Assessment: A thorough Life Cycle Assessment report is then conducted, which evaluates the environmental impacts associated with a product’s creation, use and disposal. This report must follow ISO 14040 International Life Cycle Assessment Standard.

- Draft EPD: The EPD is then drafted and undergoes rigorous verification by an independent third-party organization. The EPD must follow ISO 14025 International Standard for Developing Type III EPDs.

- Publish EPD: The EPD is published and made publicly accessible for up to five years.

Real examples of EPDs

The Canadian Wood Council has recently published their new EPDs for five Canadian-manufactured wood products. These include softwood lumber, oriented strand board, plywood, trusses and prefabricated wood I-joists. These EPDs provide comprehensive, transparent environmental data on the potential impacts from the raw material harvest to the finished product, leaving the manufacturing facility.

In summary

Environmental Product Declarations are more than just documents; they are catalysts for a more sustainable future. By providing transparent, verified and standardized information about a product’s environmental impact, EPDs empower informed choices, drive market transformation, and pave the way for a low-carbon future. As awareness and demand for sustainable products continue to grow, expect to see EPDs playing an increasingly vital role in shaping our purchasing decisions and ultimately, the health of our planet.

To learn more about EPDs and Life Cycle Assessments, visit the Carbon Leadership Forum’s toolkit or contact us.